UPM Formi 3D printing material was already selected for production of Normada´s 3D printed furniture collection use at a very early stage. “During our initial R&D phase we searched around for quite some time hoping to find a material that could mimic the tactile sense of wood somehow. Luckily, we found UPM Formi 3D biocomposite which not only looked and felt great, but also told just the right story for Normada through its cellulose fibre composition. This allowed us to rethink the notion of “What is wood?” and challenge the perception of traditional Scandinavian furniture classics in the age of Additive Manufacturing. And we are so happy with the result.” says Johanna.

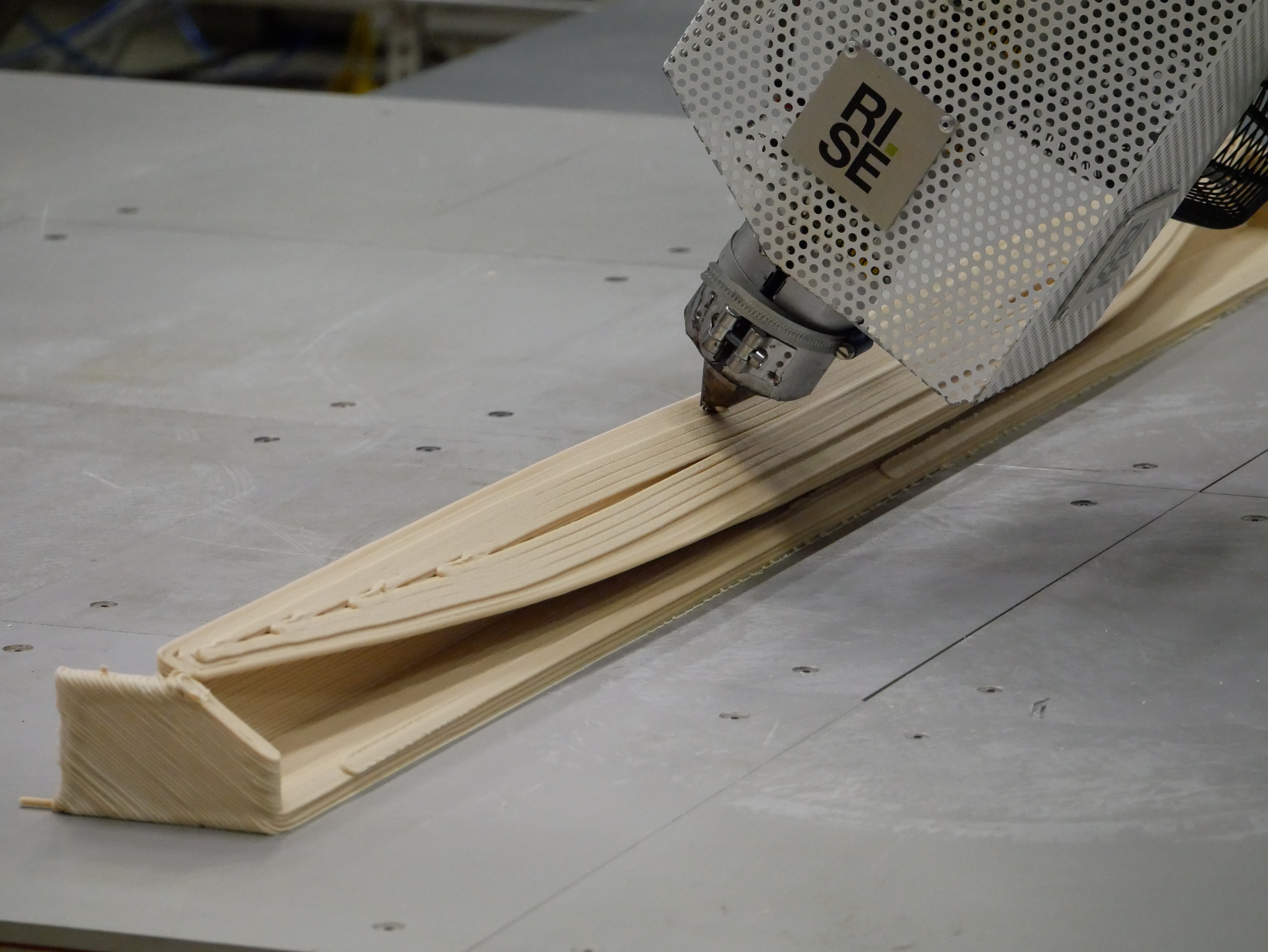

Vesterberg says that the idea behind their company is to make 100% circular furniture locally produced with local materials in the country where the customer lives. This is an excellent way to be more sustainable since no moulds are needed and no scrap is produced. 3D-printing (additive manufacturing) is a method where the material is layered on top of itself. It starts from nothing and then builds the furniture three-dimensionally layer by layer until the part is finished. This makes 3D-printing possible anywhere in the world where a large-scale 3D printer is available.

Impressive enough, Normada has a Pant system where you can request to Pant your furniture. After the request the furniture is returned to Normada and grinded down to create granules for 3D printing, and the customer gets a payment for this. If the furniture is in a good shape however it is checked by cabinet maker that is situated max 20 km from the customer and then repurposed for a new customer. If the furniture is not in such a good shape it is grinded down and used in process to create granules for 3D printing.

Check out Normada´s The Nest 3D sofa here: The Nest™ 3D (normada.se)